Bassetti Architects | Abbott Construction

Client: Bassetti Architects | FUMC Art Committee

Project: First United Methodist Church | Bronze Door Pulls | Design and Fabrication

Duration: 3.5 Months (Design and development through production)

BACKGROUND:

While working on the stainless-steel cross we were commissioned to design and create eight large-scale bronze door pulls for the narthex and sanctuary entrance doors. Oars and palm fronds, church symbols of passage and victory, informed Bassetti’s original design concept. The intent was that the symbology be recognizable but not too literal. At the onset, the lead architect gave us a small paper mock-up of oar shapes with a graceful twist in the handles. We explored this concept as well as other interpretations of oars in miniature. These were presented and two were chosen to be sculpted as full-scale concept models. Upon review the church art committee decided that these early iterations felt too realistic and specific. This prompted a question as to whether or not to model the handles after an oar. Days later we received a request from the committee that the handles somehow be representative of both the oar and the palm to suggest the story of the first Pastor, who canoed to his congregates, and the palm fronds that welcomed Jesus to Jerusalem.

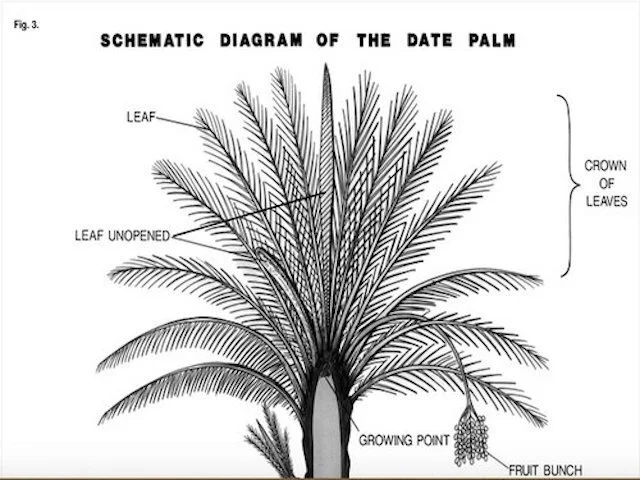

I began researching to find the palm tree of ancient bible references and learned that it was the Phoenix dactylifera date palm. Date palms have the familiar pinnate leaves comprised of separate feather-like leaflets that are attached to a central spine or rachis. However, when I looked further into leaf anatomy, I discovered that before the leaves mature enough for the leaflets to separate, they are solid and resemble a shape similar to the paddle of an oar. This new information seemed to furnish the perfect solution. We immediately began designing and sculpting from this shape. To achieve a thinner leaf/paddle form and execute a graceful twist like the original Bassetti mock-up, I devised a flat armature from sheet metal that we twisted gradually from the leaf shape and carried through the transition to the handle. The armature also supported a higher arch in the handle. On one iteration the handle terminated much like the original oar mock-up. On the other I contoured and curved the end of the handle so that it terminated into the door. We received design sign-off on the second iteration and sculpted the final pair of clay patterns over similar armatures modified for the casting process. We would have preferred to do the casting ourselves. However, given the short lead time, I arranged to have Walla Walla Foundry handle the casting. Should anything go awry during the process, they would have the staff and resources to recast quickly.

Since much of the detailing work was fragile, we took the patterns to Walla Walla and did the final detailing at the foundry. This included adding plugs to precise corresponding positions on the back of each leaf. These would cast as tenons to fit mortises in the doors, allowing the leaf portion to lay flat against the surface while concealing a stronger method of attachment. The last and most labor intense step of the detailing was to add consistent low relief texture to the entire surface of each pull.

It is standard practice to cast larger objects so that they are hollow to reduce weight and the volume of bronze used in the pour. These pulls were just over 52-inches tall with relatively slender handles and a long span between points of attachment. To improve the structural integrity where the pulls would take the most stress from use, we chose to have them cast solid. Although all eight pulls would originate from the same pair of clay patterns, the individual mold making, and casting processes would give each a different character.

After completion, Walla Walla shipped them back to the studio. We designated the pulls for specific doors as singles and pairs based on their characteristics. That was followed by machining the tenons and base of the handles in preparation for installation. Next we fabricated sixteen solid brass escutcheons to conceal the fastening on the interior side of the doors. Each pull was then fitted and fastened to a corresponding right or left side facing door-section mock-up. These mock-ups would keep the pulls stable during transport, and also serve as installation templates for the contractor.